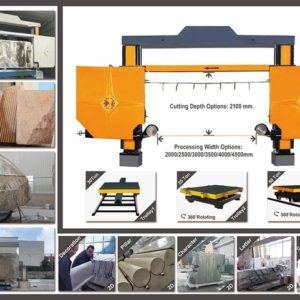

Stone Wire Saw Machine for Block Cutting adopts CNC control, Four-Axis linkage, which can process the circular stone slab, roman column, numeral, letter, Chinese characters and other designed shapes.

1, The flywheel elevates and lowers along these guide rails. the flywheel works stably which improves the service life of the diamond wire saw.

2, Solid and hollow stone column, Roman column, large solid line, Numbers, letters, Chinese characters and a variety of complex shapes for marble, granite.

3, More than 20 years Stone Machinery Manufacturing Experiences.,12month warranty.

4, Top Quality, Reasonable Price ,Best Performance.,Solid and hollow stone column, Roman column, large solid line, Numbers, letters, Chinese characters and a variety of complex shapes for marble, granite.

5, Stable and constant stretch on the flywheels enhances the cutting accuracy.,The machine process stone with high machining precision and good quality.

1. It has heavy load bearing structure, four orbits on each upright column, adjusted the balance by the rollers, with less friction and higher precision.

2. The left and right frame achieve synchronized lifting by steering equipment on the upper frame. The lifting accuracy increased by the conbine of lead screw and double nuts.

3. Cantilever part, firstly the lead screw and pole adjust the distance of guide wheel,guide wheel is controlled by CNC. Secondly in order to make the diamond wire rope cutting direction coincidence, reducer control the guide wheel rotating angle.

4. Worktable is running by lead screw and railway.

5. There has automatic alarm and memory function if wire broken, on top of it.

6. Aluminum wheel diameter is 1600mm.One fly wheel slide through sheave, oil pump control rope tension.

| Model | Unit | SCTSJ-2000 | SCTSJ-2500 | SCTSJ-3000 |

| Max. process size | mm | 3000*2000*1500 | 3000*2500*1500 | 3000*3000*1500 |

| Working table size | mm | 2500*1300 | ||

| Wire length | mm | 13000 | 14000 | 15000 |

| Wire diameter | mm | 7.6-11 | ||

| Cutting linear speed | m/s | 25-45 | ||

| Main motor power | kw | 11 | ||

| Water consumption | M³/h | 2 | 3 | 4 |

| Overall dimension | mm | 6300*6500*4000 | 6300*7000*4000 | 6300*7500*4000 |

| Approximate weight | kg | 5300 | 6200 | 6800 |