Marble Chain Saw Machine can cut all kinds of marble,lime stone whose hardness is less than 5.

Working Details

Our arm chain saw cutting marble and stone machine can work efficiently in the quarry:

1.On the rails, the machine can rapidly adjust oil cylinder action by the hydraulic pressure drive.

2.The chain arm may rotate in 360 degree for vertical and horizontal cutting which can translate freely according to the mining requirement.

3.The cutting chain is transmitted by motor through a gearbox, making stepless speed regulation within 0-1.2m/s by frequency control chain speed.

4.the hydraulic motor drives the platform moving back and forth and the 360 degree rotation of chain arm, both having two speeds (fast and slow).

5.the cutting speed can be adjusted according to the hardness of stone, the hydraulic system is equipped with automatic heating and air cooling device, which can ensure the equipment can work normally when the environment temperature difference is substantia.

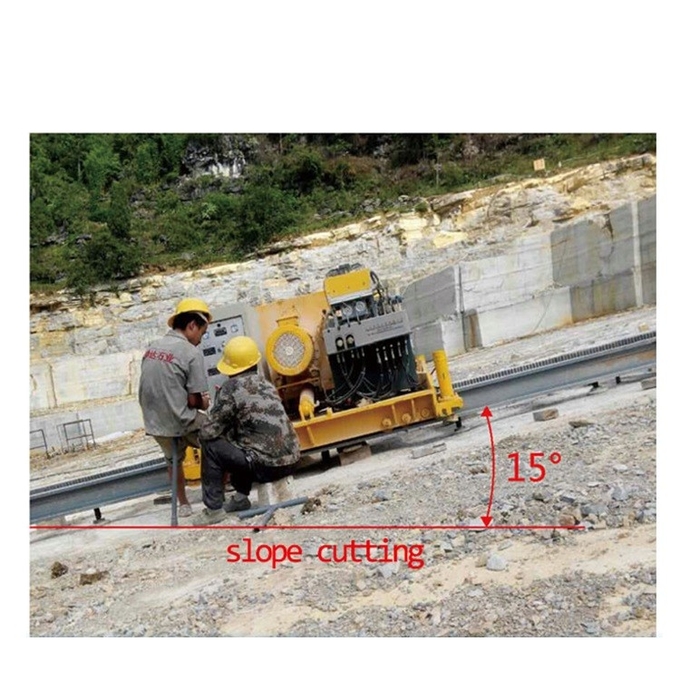

• Different Cutting Directions

a.Arm can rotating 360º,and working both horizontal and vertically.

b.Wet and dry cutting.

c.The rail could automatically move on horizontal direction.

• Main Characters

a.No limit for the distance of cutting by combination rail.

b.Minimizing Waste, no effect for the structure of block and it is easy to check the quality of block.

c.To be compare with the wire-saw, the Chain Saw does not need pre-drilling, and does not have the problem of breakage and connection of wires.

d.The shape of blocks cutted by Chain Saw is tidiness, doesn’t need shaping.

e.The cutting cost is very low, only one person can manipulate it.

f.Accessories with high quality and high precision is your good guarantee for non-stop quarrying.

g.The arm uses reinforced steel with high strength, high heat resistence and bending resistance.

h.The fools are with high hardness of carbonized tungsten, anti-abrasive and easy to change.

i.4 set oil hydraulic cylinder could be operated in dependently and it is easy for rail to fixing position and adjusting level.

j.A set of tips (widia) could cut 60~180 square meter in terms of hardness of marble stone.(a piece of tip can use 4 edge for cutting).

k.A set of chain can work for 600 hours.

| Model | LBJ-2000 | LBJ-2500 | LBJ-3000 | LBJ-3500 |

| Cutting performance: | 2-5 M2/h | 2.5-6 M2/h | 2.8-7.5 M2/h | 3-10.5M2/h |

| Max deepth of slot | 2000MM | 2500MM | 3000MM | 3500mm |

| Width of slot: | 40MM | 40MM | 40mm | 40mm |

| Moving speed of machine: | 0-230MM/MIN | 0-230MM/MIN | 0-230mm/min | 0-230mm/min |

| Arm speed : | 0-1.8R / H | 0-1.8r / h | 0-1.8r / h | 0-1.8r / h |

| Chain rotation: | 0-80r/m | 0-80r/m | 0-80r/m | 0-80r/m |

| Total power: | 32kw | 32kw | 40kw | 40kw |